Main features:

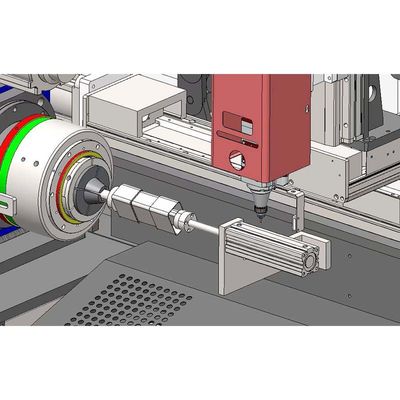

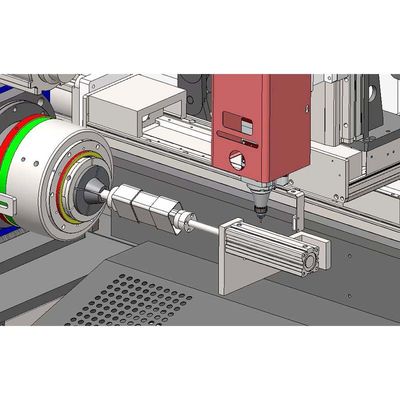

- Strong adaptability to materials, able to adapt to the cutting and processing of various irregular small hardware parts;

- High production efficiency, which can replace traditional manufacturing processes such as CNC punching, shearing, and manual work;

- Fast cutting speed, no edge collapse phenomenon, no damage to the workpiece, with a high yield rate;

- High cutting accuracy, smooth cut surface without burrs, good verticality, and no need for subsequent secondary processing;

- The operation is simple and fast, with a rich process database embedded, which can be called or modified with one click;

- Stable and reliable performance, efficient and energy-saving, low maintenance costs, and long service life;

- Various non-standard models and fully automatic feeding devices can be customized to shorten the feeding time;

- Green and environmentally friendly processing, no pollutants, no consumables, and high yield rate;

Ordering Guide: Model STC-XXXX-YY-AABB

|

STC

|

XXXX

Laser power (W)

|

YY

model

|

AA

X-axis stroke

|

BB

Travel Y-axis

|

|

laser cutting

|

1500

|

BS: Standard version

|

01:100mm

|

04:400mm

|

|

2000

|

DS: Dual workstation model

|

02:200mm

|

06:600mm

|

|

t3000

|

EE: Eccentric style

|

|

08:800mm

|

| |

TE: Fully enclosed pneumatic chuck

|

|

10: 1000mm

|

| |

10: 1000mm

|

Other customizations

|

Other customizations

|

Optional:

1.Standard BS

2.dual workstation DS

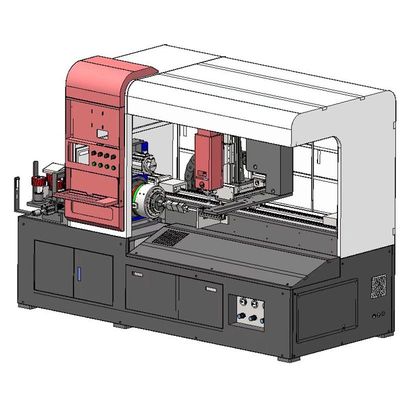

Integrated row and dual workstation design, dual effect linkage "fast" imagine;

Efficiency increased by 100%, purchase cost and land occupation decreased by 50%, and can independently cut the same or different workpieces synchronously or asynchronously without interference, making it the king model for laser processing of small metal pipes.

3.Eccentric EE

Tailored tire molds, ejector pins, and eccentric structures; It can quickly cut various irregular structural hardware components to achieve a significant increase in efficiency, production capacity, accuracy, and economic benefits with less floor space and lower purchasing costs.

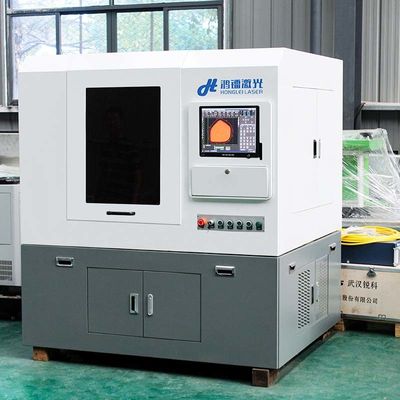

4 fully enclosed pneumatic chuck models TE

Fully enclosed sealing structure intervenes to block light and debris, protecting operators and the environment; Fully automatic self centering pneumatic chuck, super intelligent automatic clamping technology, four claw roller type clamping, automatic centering, can automatically adjust and adapt the workpiece according to the customer's pipe size, without scratching the workpiece, without manual labor, small inertia, and can achieve high-speed processing. It can also be equipped with claw clamping to hold multiple types of profiles, meeting the needs of fast cutting of various small pipe parts.

Application field:

Mainly suitable for high-precision hole cutting, slotting, hollowing out, and arc cutting of various irregular small hardware parts and circular pipes, square pipes, bent pipes, variable pipes, U-shaped pipes, curved pipes, and curved hardware within 1.5 meters. It has fast cutting speed, smooth cuts, good verticality, one-time forming, and no need for subsequent polishing and processing. Widely used in hardware lighting, kitchenware, automotive oil pipes, instrument panel pipe racks, electric tools, exhaust pipes, stainless steel furnace cores, automotive hardware fittings, etc.

Sample display:

After-sales service & Customer visiting:

1.fiber laser cutting tube machine 1 years warranty except consumable parts;

2.Plenty of technical support online is available;

3.Quick Back-up Parts Available&Technical Assistance;

4."Training Video","Instruction Book",and"Operation Manual"will be offered;

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Q: Are you factory or trading company?

A: We are an OEM factory with many experience.

Q: What's your MOQ?

A: We don't have MOQ. No matter 1 set order or 100 set order, we will give you support with our heart and soul.

Q: How do your factory do regarding quality control?

A: Quality is priority. Each OREE laser machine will be tested by 24 items. After all the 24 items passed, then our QC do 48~72 hours reliability test. Our laser machines has gained CE.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!